Underwater parts of a vessel, such as hull surface, the boards, screw-steering group, sea chest screens and boxes etc. are subjected to biological growing, exfoliation and corrosion of paint. As a result, the increase of roughness of the hull, occurs and consequent, surface deterioration of its running characteristics as well as fuel overconsumption.

It is known that increase of roughness at 1 mm results in 1% increase in the fuel consumption . The intensity of biological growing for one navigation makes on the average: in northern seas of 3-5 kg/sq.m, in the tropical seas - more than 50 kg/sq.m with the thickness of biological growing up to 20 sm.

Lately, the regular underwater cleaning without putting a vessel to a dock has begun widely applied in the world practice. As a rule the economic benefit of such cleaning is very high: for example, the regular cleaning in the interdock period of an underwater part of the hull of the tanker by 50 thousand tons displacement from biological growing for one year of its operation saves 950 tons of diesel fuel, i.e. up to USD 242000 (according to "Phosmarine Equipment S.A.").

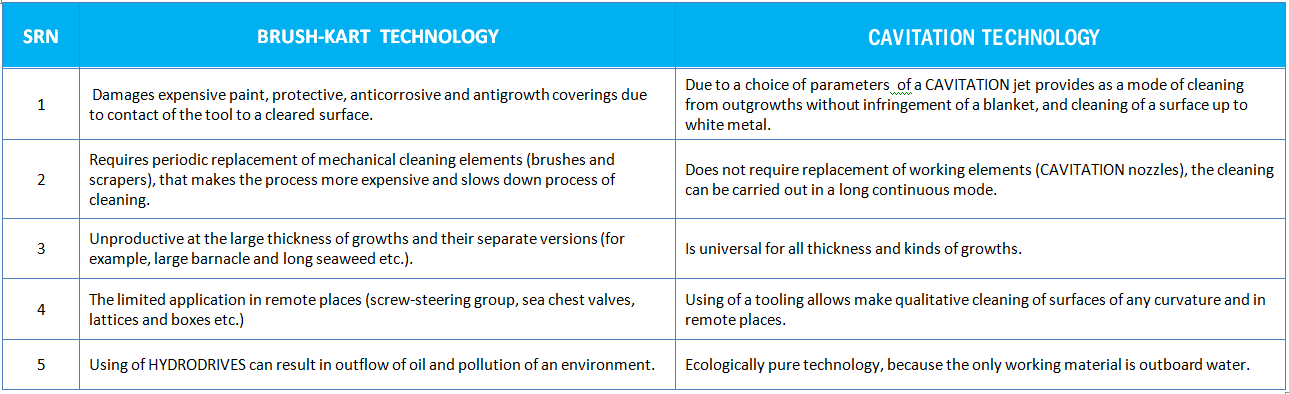

This work is carried out by the divers with the help of scrapers or mechanical brushes ("BRUSH-KART" technology) with the productivity of cleaning from 5 up to 800 sq.m per hour at the cost of cleaning up to USD 15 per 1 sq.m of a vessel's underwater surface. The given speed and cost restrictions of mechanical cleaning are explained by the fact that the divers scrape and beat off growths coat by coat, because at the large thickness they stick together with each other reaching the concrete durability. Besides due to the contact of the tools with a cleansed surface expensive protective anticorrosive coverings could be damaged.

The proposing cavitation technology is free from the specified lacks, as for removal of outgrowths it uses destroying action of cavitation. The basic part of a complex is cavitation jet generator in which water, passing under the pressure of 75-150 atm., is filling by microscopic nucleuses formed from the dissolved gases, and is pulling out from nozzle, directed on a cleaned surface. When contacting with surface nucleuses crack, and in these points the pressure reaches thousand atmospheres, that results to exfoliation of growing from a surface.

Adjusting pressure of a cavitation jet, it is possible to keep protective paint layer, and if it already degrade, at the expense of the raised energy and direction of a jet, it possible to remove this layer with a rust up to white metal.

Comparison of technologies BRUSH-KART and CAVITATION